Product Details

AQUILOX AQUA LLP offers latest technologies in the field of water and wastewater treatment. Membrane Bioreactor is one of them which is most promising to treat the wastewater to a higher degree and this treated water can be recycled for the process applications in various industries.

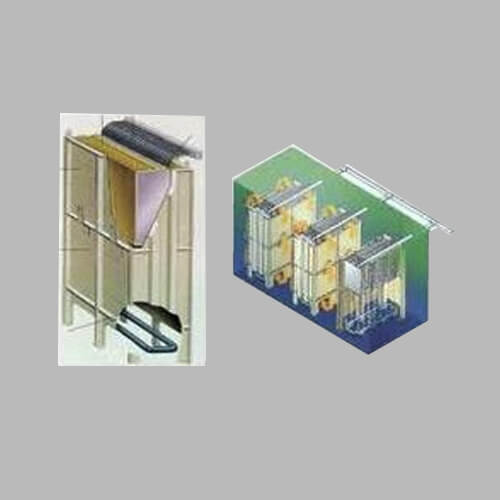

The Membrane Bioreactor is a simple, but very effective combination of the activated sludge treatment process and the membrane filtration process. Imagine an activated sludge aeration basin, with sets of micro- or ultra-filtration membrane filtration modules submerged in the aeration basins, and it is MBR.

The wastewater enters the wastewater treatment facility and passes through the usual Preliminary treatment, and Primary Treatment processes. The dissolved BOD (sugars, starches, carbohydrates, etc) that is in the wastewater is then consumed by the microbes in the aeration basin, and subsequently converted into additional microorganisms, or becomes attached to the biological floc. The Mixed Liquor Suspended Solids (MLSS) is usually fairly high in MBR units, around 10,000 mg/L to 15000 mg/L. This high MLSS concentration allows for lower hydraulic retention times (HRT) which equates to smaller aeration basins.

AQUILOX AQUA LLP membrane filtration process produces an effluent extremely low in suspended solids concentration and turbidity units. The quality of this water, when the process is properly operated, is amazing.

Advantages Of AQUILOX AQUA LLP MBR

- The effluent is of very high quality, very low in BOD (less than 5-10 mg/l), very low in turbidity and suspended solids. The technology produces some of the most predictable water quality known. It is fairly easy to operate as long as the operation has been properly trained, pays strict attention to the proper operation, corrective maintenance, and preventative maintenance tasks.

- The “simple filtering action” of the membranes creates a physical disinfection barrier, which significantly reduces the disinfection requirements.

- The capital cost is usually less than for comparable treatment trains.

- The treatment process also allows for a smaller “footprint” as there are neither secondary clarifiers nor tertiary filters which would be required to achieve similar water quality results. It also eliminates the need for a tertiary backwash surge tank, a backwash water storage tank, and for the treatment of the backwash water.

- Generally speaking it produces less waste activated sludge than a simple conventional system.

- If re-use is a major water quality goal, the MBR process will be a major consideration. This process produces a consistent, high water quality discharge. When Reverse Osmosis (RO) water quality is required, the MBR process is an excellent candidate for preparing the water for RO treatment.